Our Company is managed by Mr. Ashutosh Agrawal. He has done MS from USA with seven years of working experience there in US.

We are manufacturing and exporting our wide range of woven and non woven products, Poly film and paper products under guidance of Mr. Rashmikant Agrawal, who is having rich experience of more than 30 years in this industry. We make Back Seam bags with State of Art Technology. We have capacity to make 100,000 Paper laminated woven Back Seam bags (known as Paper poly woven bags or Paper-plastic compound bag) per day. We also make Circular and Back Seam PP woven and BOPP bags, PP/PE woven and Laminated & Printed Fabrics for bags & Wrapping, PP non woven Plain Laminated and Metallic Laminated fabrics for Shopping bags, Poly Liners, Poly coated Papers Exporter in Nigeria, Ethiopia, Egypt, South Africa etc.

Global Reach : Our commitment to quality and customer satisfaction has earned us a broad client base across the USA, UK, Canada, Europe, and Africa. We continually strive to expand our market presence and deliver superior products that meet the highest standards of excellence.

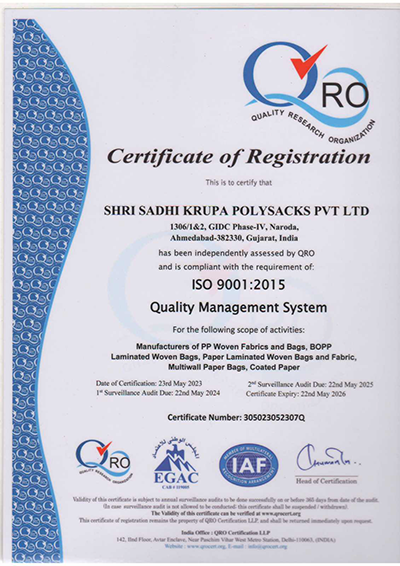

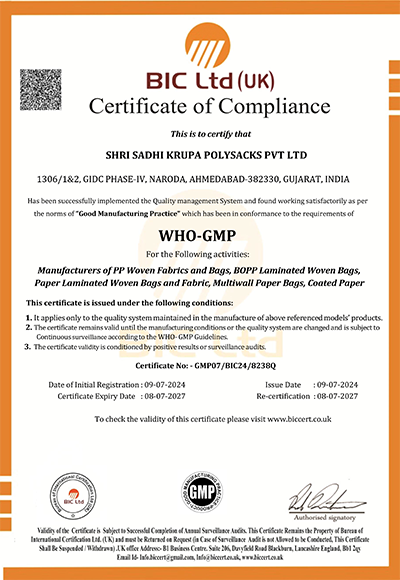

We have attained the following memberships and accreditations

- MSME ( ministry of micor small & medium enterprise)

- DGFT ( directorate general of foreign trade)

- THE PLASTIC EXPORT PROMOTION COUNCIL

- MAKE IN INDIA

- ECGC ( export credit guarantee corporation of india limited )

udhyogaadhar

Customized Product

We customized product as per customer requirement.

We Experiences

We are manufacturing and exporting our wide range of woven and non woven products, Poly film and paper products under guidance of Mr. Rashmikant Agrawal , who is having rich experience of more than 30 years in this industry. We make Back Seam bags with State of Art Technology.

Art Of Technology

State of the art technology.

Land & Building

We have two units, one is for making woven fabrics and another is for extrusion coating, Printing, Tubing and finishing.

Plant & Machinery

1) Plant & Machinery

- Tape Plant

- Circular Looms

- Extrusion Coating Plant-Tendom

- LD-LLD-HM Liner/film plant- 1000 mm wide tube

- Liner cutting sealing machine

- Six color Roll to Roll Flexo Printing Machine- six color, 1250 mm printing width

- Tubing plant

- Auto sewing machine

- B.C.S – Back Cutting and Sewing Machine

- Normal double/single needle sewing machines

- Bag printing machine-two color

- Fabric opening, sliting, rewinding machine

- Fabric cutting machine Automatic

2) Lab Testing Machines/Instruments

- Tensile Testing Machine

- Denier/gsm testing machine

- Paper GSM and BF testing Machine

- RPM testing instrument

- Temperature testing instrument

- Filler Testing Machine

- Drop Testing Machine

- Anti Skid Testing

- Ash Testing Machine